How Flarelock Exhaust Hoses Work: A Comprehensive Guide

With automotive repair and maintenance, effective ventilation of exhaust fumes is crucial for both safety and operational efficiency. Flarelock exhaust hoses are a popular solution, offering a unique blend of durability, flexibility, and ease of use. These innovative hoses are specifically designed to meet the demanding requirements of automotive repair facilities, workshops, and garages.

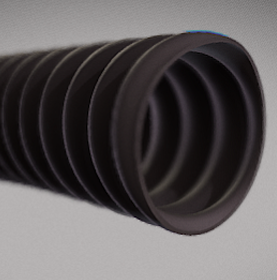

Unlike traditional hoses that may collapse or sustain damage when run over by vehicles or heavy machinery, flarelock hoses feature a unique convoluted design. This design allows the exhaust hose to temporarily flatten under pressure and then return to its original shape once the pressure is removed. The resilience of flarelock hoses is excellent in workshop environments where hoses are often laid across the floor or used in underground applications.

Flarelock Hose Composition

The material composition of flarelock hoses is another key factor in their performance. These hoses are made from a specially formulated rubber compound so that they can withstand intermittent temperatures of up to 600°F (315°C). This high heat resistance is crucial when dealing with hot exhaust fumes directly from vehicle tailpipes.

WARNING: Vehicle Exhaust is extremely dangerous and potentially deadly. We always recommend that any system be properly engineered to meet the specifications of your application. If you are using our Crushproof system, we recommend that you use it with a fan and as an intermittent repair solution only, not to be run for long periods of time. This hose is to be used only with naturally aspirated 4 cycle engines running at an idle and under no load. We recommend keeping any run of hose as short as possible preferably 11' or under and sized to include ambient air to cool the exhaust temperatures. This hose is designed to handle frequent temperatures up to 400° and intermittent temperatures to 600°. When using Crushproof hose for the first time, watch closely to verify that the exhaust is exiting the building as designed. IF YOU SEE ANY EXHAUST COMING BACK INTO THE SPACE, THE HOSE IS NOT BEING USED PROPERLY. TURN THE VEHICLE OFF IMMEDIATELY AND CALL OUR EXPERTS.

WARNING: Vehicle Exhaust is extremely dangerous and potentially deadly. We always recommend that any system be properly engineered to meet the specifications of your application. If you are using our Crushproof system, we recommend that you use it with a fan and as an intermittent repair solution only, not to be run for long periods of time. This hose is to be used only with naturally aspirated 4 cycle engines running at an idle and under no load. We recommend keeping any run of hose as short as possible preferably 11' or under and sized to include ambient air to cool the exhaust temperatures. This hose is designed to handle frequent temperatures up to 400° and intermittent temperatures to 600°. When using Crushproof hose for the first time, watch closely to verify that the exhaust is exiting the building as designed. IF YOU SEE ANY EXHAUST COMING BACK INTO THE SPACE, THE HOSE IS NOT BEING USED PROPERLY. TURN THE VEHICLE OFF IMMEDIATELY AND CALL OUR EXPERTS.